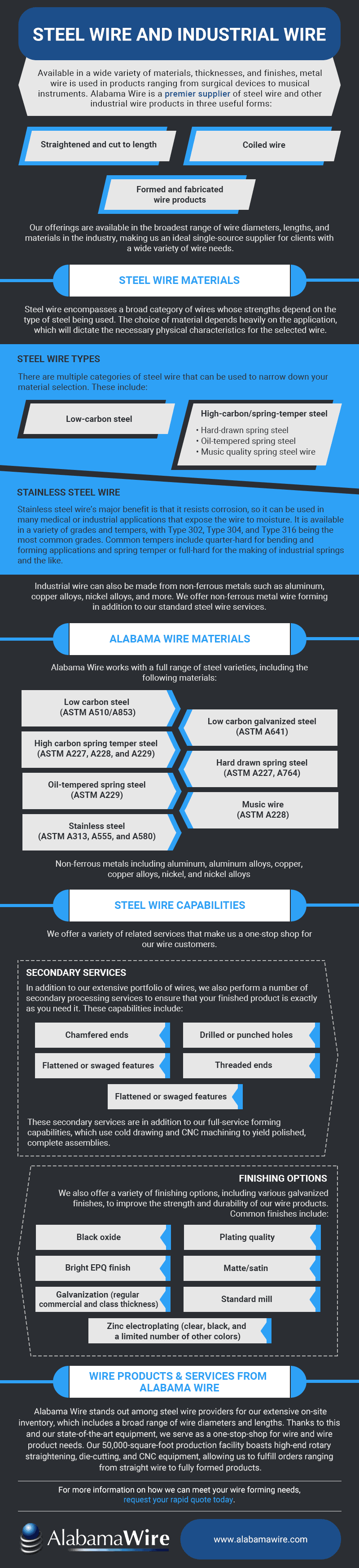

Available in a wide variety of materials, thicknesses, and finishes, metal wire is used in products ranging from surgical devices to musical instruments. Alabama Wire is a premier supplier of steel wire and other industrial wire products in three useful forms:

- Straightened and cut to length. We combine rotary straightening with close-tolerance circular die-cutting to produce precise, clean cuts to your exact specifications. Secondary services are available to customize the final product, including flattening, deburring, swaging, chamfering, and finishing.

- Coiled wire. Our facility is fully stocked with a broad inventory of wire types and wire diameters, allowing us to fulfill bulk coiled and re-coiled orders on demand. These capabilities also extend to high-temper grades such as hard-drawn and oil-tempered spring steel wire.

- Formed and fabricated wire products. We also offer cold-drawn wire formed and fabricated to specific shapes and configurations. We use advanced CNC technology to efficiently produce component parts, custom wire forms, and fabricated 2D or 3D wire products.

Our offerings are available in the broadest range of wire diameters, lengths, and materials in the industry, making us an ideal single-source supplier for clients with a wide variety of wire needs.

Steel Wire Materials

Steel wire encompasses a broad category of wires whose strengths depend on the type of steel being used. The choice of material depends heavily on the application, which will dictate the necessary physical characteristics for the selected wire. Our experienced sales staff can help you determine which wire type is the most appropriate for your project.

Steel Wire Types

There are multiple categories of steel wire that can be used to narrow down your material selection. These include:

- Low-carbon steel. Low-carbon steel is a non-alloyed material with a low carbon content, which gives it a moderate tensile strength compared to other choices. For this reason, low carbon steels are ideal for applications where the wire will need to bend easily. Low carbon steel is highly weldable, making it an excellent material for inclusion in welded assemblies. Low carbon steel wire is often galvanized to provide a more durable surface finish.

- High-carbon/spring-temper steel. Spring temper steel features a higher carbon content that leads to high tensile strength in the cold-drawn condition. It is used extensively in the manufacture of industrial springs, but is also used in a wide variety of other applications that require the part to withstand high stress and deflection but retain its original shape. These applications include hooks, clips, retainers, torsion bars, and other parts used in automotive, transportation, and many other types of commercial and industrial equipment. High carbon spring steel wire comes in three broad categories:

- Hard-drawn spring steel. Hard-drawn spring steel wire, also referred to as HDMB spring steel wire, is a sturdy, cost-effective option for many general-purpose applications. As it is not typically heat treated after drawing, it exhibits high strength and moderate toughness. Hard-drawn spring steel wire is available in a wide range of diameters.

- Oil-tempered spring steel. Oil-tempered spring steel wire, also referred to as OTMB spring steel wire, is an excellent general-purpose spring wire with improved properties compared to Hard Drawn. After drawing, oil-tempered undergoes heat treatment and controlled cooling in an oil bath to increase its toughness while retaining high tensile strength. This makes it especially suitable in applications requiring high impact resistance or high numbers of deflection cycles. Oil-tempered wire is available in a wide range of diameters.

- Music quality spring steel wire. Music wire is best known as the type of wire used for piano strings. However, as a high-carbon, heat-treated wire with excellent stress and impact resistance, it can also be used in many other settings. Music wire is generally limited to diameters of 0.250” and smaller.

- Stainless steel wire. Stainless steel wire’s major benefit is that it resists corrosion, so it can be used in many medical or industrial applications that expose the wire to moisture. It is available in a variety of grades and tempers, with Type 302, Type 304, and Type 316 being the most common grades. Common tempers include quarter-hard for bending and forming applications and spring temper or full-hard for the making of industrial springs and the like.

Industrial wire can also be made from non-ferrous metals such as aluminum, copper alloys, nickel alloys, and more. We offer non-ferrous metal wire forming in addition to our standard steel wire services.

Alabama Wire Materials

Alabama Wire works with a full range of steel varieties, including the following materials:

- Low carbon steel (ASTM A510/A853)

- Low carbon galvanized steel (ASTM A641)

- High carbon spring temper steel (ASTM A227, A228, and A229)

- Hard drawn spring steel (ASTM A227, A764)

- Oil-tempered spring steel (ASTM A229)

- Music wire (ASTM A228)

- Stainless steel (ASTM A313, A555, and A580)

Non-ferrous metals including aluminum, aluminum alloys, copper, copper alloys, nickel, and nickel alloys

Steel Wire Capabilities

We offer a variety of related services that make us a one-stop shop for our wire customers.

Secondary Services

In addition to our extensive portfolio of wires, we also perform a number of secondary processing services to ensure that your finished product is exactly as you need it. These capabilities include:

- Chamfered ends

- Flattened or swaged features

- Drilled or punched holes

- Threaded ends

- Welded rings or rectangular frames

These secondary services are in addition to our full-service forming capabilities, which use cold drawing and CNC machining to yield polished, complete assemblies.

Finishing Options

We also offer a variety of finishing options, including various galvanized finishes, to improve the strength and durability of our wire products. Common finishes include:

- Black oxide

- Bright EPQ finish

- Galvanization (regular commercial and class thickness)

- Plating quality

- Matte/satin

- Standard mill

- Zinc electroplating (clear, black, and a limited number of other colors)

Industries Served

We serve all manner of industries that employ wires or wire assemblies in their operations. Some of the industries we serve include:

- Agricultural

- Appliances

- Automotive

- Concrete vaults and poles

- Construction

- Consumer goods

- Displays and signage

- Fasteners

- Foundries

- Furniture

- Hardware

- Heating, ventilation, and air conditioning (HVAC) equipment

- Industrial machinery

- Lawn and garden equipment

- Leisure and recreational goods

- Machine shops

- Medical devices

- Nurseries and horticulture

- Packaging

- Shelving

- Sporting goods

- Spring manufacturing

- Steel service center and supply

- Transportation equipment

Wire Products & Services From Alabama Wire

Alabama Wire stands out among steel wire providers for our extensive on-site inventory, which includes a broad range of wire diameters and lengths. Thanks to this and our state-of-the-art equipment, we serve as a one-stop-shop for wire and wire product needs. Our 50,000-square-foot production facility boasts high-end rotary straightening, die-cutting, and CNC equipment, allowing us to fulfill orders ranging from straight wire to fully formed products.Our wire cutting and straightening clients also benefit from the following features of our full-service operations:

- Affordable production for order sizes ranging from prototyping to bulk orders

- Rapid prototyping on all production run sizes

- Access to a broad inventory of wire types, as well as major wire drawing operations nationwide

- Diverse product line, such as a full line of nursery plant stabilization items (primarily baskets, hooks, and tree stakes)

- Quick response times on quotations—we strive to maintain a two-hour response time, although custom orders may require slightly more time

- Secure packaging, ensuring product integrity and safety during shipping

We would be happy to speak with you about your specific wire straightening, cutting, coiling, or forming needs. Our responsive customer service team strives to answer inquiries as quickly as possible to allow you to make fast and informed buying decisions. For more information on how we can meet your wire forming needs, request your rapid quote today.